What Supply Chains Looked Like Before Digital Transformation

9/15/2025

Introduction

Digital transformation in supply chains refers to the integration of advanced technologies—such as artificial intelligence, big data analytics, cloud computing, and the Internet of Things—into logistics and operations. Unlike traditional, linear supply chains that often relied on manual processes, siloed information, and reactive decision-making, today’s supply chains are becoming smarter, interconnected, and highly responsive. This shift is being driven by the increasing complexity of global trade, rapidly changing customer expectations, and disruptions such as geopolitical shifts or pandemics, which have highlighted the need for greater efficiency and adaptability. The growing demand for agility, visibility, and resilience has redefined the way businesses approach logistics. Previously, supply chains focused heavily on cost efficiency and predictability, but they lacked the real-time data and transparency required to respond quickly to unexpected changes. Digital transformation has changed the game by enabling predictive analytics for forecasting, end-to-end visibility across global networks, and automation that accelerates decision-making. As a result, companies can now anticipate disruptions, adjust operations dynamically, and build more resilient systems that balance efficiency with flexibility. In short, the modern digital supply chain moves beyond being a cost center—it is now a strategic enabler of competitiveness and long-term growth.

What Supply Chains Looked Like Before Digital Transformation

Before digital transformation, traditional supply chains were largely dependent on manual workflows and outdated practices that limited efficiency. Businesses often relied on spreadsheets, phone calls, and endless streams of paperwork to manage shipments, inventory, and vendor communications. This approach, while functional at the time, was time-consuming and error-prone. The reliance on legacy systems further compounded the problem, as these systems lacked integration and could not provide a holistic view of operations. As a result, teams struggled with fragmented information and inconsistent data, leading to frequent miscommunication between departments and external partners. One of the most significant challenges was the lack of real-time visibility into shipments and inventory. Organizations operated reactively, often finding out about delays or shortages only after they had already impacted operations. Because data was siloed across multiple systems and stakeholders, decision-making was slow and based on incomplete or outdated insights. This inefficiency translated into higher operational costs, as businesses had to deal with unnecessary delays, excess inventory, and manual error corrections. In essence, pre-digital supply chains lacked the agility and transparency needed to respond effectively to disruptions, leaving companies vulnerable in an increasingly fast-paced and interconnected global marketplace.

The Trigger for Change: Why Companies Embraced Digital Transformation

The trigger for change in supply chains came from a combination of rising pressures and new opportunities that forced companies to rethink outdated practices. Customers began demanding faster delivery, greater transparency, and higher accuracy in their orders, setting new benchmarks for performance. At the same time, globalization created increasingly complex supply networks that spanned multiple regions, vendors, and regulatory systems. Managing this complexity with manual processes was no longer sustainable. These challenges acted as powerful business transformation drivers, making supply chain modernization not just an option but a necessity for organizations that wanted to remain competitive. Alongside these pressures, digital disruption in logistics brought a new wave of solutions powered by Industry 4.0 technologies. Advances in artificial intelligence, automation, the Internet of Things, and big data analytics offered companies the tools to address inefficiencies, cut costs, and build resilience. Organizations recognized that adopting digital solutions could not only streamline operations but also provide predictive insights and real-time visibility across the supply chain. By embracing digital transformation, businesses positioned themselves to meet customer expectations, adapt quickly to disruptions, and drive long-term growth. Ultimately, the convergence of rising demands and technological innovation set the stage for a fundamental reinvention of supply chain management.

After Digital Transformation: A Supply Chain Success Story

Case study

Consider the story of a global retail company that struggled with outdated practices before embracing digital transformation. Inventory tracking was slow and dependent on manual counts, which often led to errors and stockouts. Communication between warehouses, suppliers, and distributors was fragmented, with each department using different tools and processes. When disruptions occurred, the company relied on reactive problem-solving, often discovering issues only after they had escalated into costly delays. This traditional model limited growth, increased operational costs, and left customers frustrated by inconsistent service levels. After adopting a smart supply chain approach, the business transformed its operations end-to-end. Real-time tracking became possible through IoT-enabled sensors, allowing the company to monitor inventory levels and shipments with complete accuracy. Communication was unified through centralized, cloud-based platforms that connected suppliers, logistics partners, and internal teams seamlessly. Predictive analytics, powered by AI in supply chain operations, shifted the company’s strategy from reactive to proactive, enabling it to anticipate disruptions and optimize decision-making. Automation in logistics streamlined warehouse operations, reduced errors, and improved speed. This digital overhaul not only cut costs but also enhanced resilience and customer satisfaction, showcasing how technology-driven modernization can turn long-standing supply chain challenges into a competitive advantage.

Highlight measurable improvements

The impact of digital transformation in supply chains is best seen through measurable improvements that directly affect both operations and customer experience. Companies that have embraced a smart supply chain approach report significant cost reductions, as automation in logistics minimizes manual errors, optimizes warehouse workflows, and streamlines transportation routes. Real-time tracking of shipments and inventory reduces waste and excess stock, ensuring that resources are allocated efficiently. Faster delivery times have become a new standard, as digital tools enable companies to anticipate demand and manage capacity with greater accuracy. These operational gains translate into higher productivity and reduced expenses, allowing businesses to achieve more with fewer resources. Beyond efficiency, the benefits extend to customer relationships and long-term resilience. Improved customer satisfaction is a direct result of transparency and reliability enabled by digital solutions. With real-time tracking, customers receive accurate updates on their orders, building trust and loyalty. At the same time, AI in supply chain systems strengthens risk management by predicting potential disruptions, from supplier delays to geopolitical issues, and enabling proactive responses. These measurable improvements highlight that digital transformation is not simply about adopting new technologies—it is about creating a supply chain that is faster, smarter, and more resilient in a rapidly evolving market.

Key Technologies Powering Supply Chain Digital Transformation

Digital transformation in supply chain management has been driven by a set of powerful technologies that redefined how businesses operate. Cloud ERP and SaaS platforms have replaced fragmented legacy systems with integrated, cloud supply chain platforms that enable real-time collaboration across vendors, partners, and internal teams. IoT sensors and RFID tags provide real-time tracking of inventory and shipments, ensuring unprecedented supply chain visibility and accuracy. These smart logistics solutions give companies the ability to monitor conditions like temperature, location, and delivery timelines, significantly reducing delays and errors. Compared to legacy vs modern supply chains, the difference is clear—data once trapped in silos now flows seamlessly across the entire network. Artificial Intelligence and Machine Learning are transforming decision-making by enabling predictive analytics, demand forecasting, and dynamic optimization of resources. Robotics and supply chain automation have accelerated warehouse operations, from picking and packing to autonomous vehicles in logistics hubs. Blockchain technology adds another layer of trust and transparency, allowing stakeholders to verify transactions, trace product origins, and strengthen compliance. Together, these innovations in AI in logistics, automation, and secure data management make modern supply chains faster, more efficient, and more resilient. This convergence of technologies marks a fundamental shift toward smarter, more connected, and agile supply chain ecosystems.

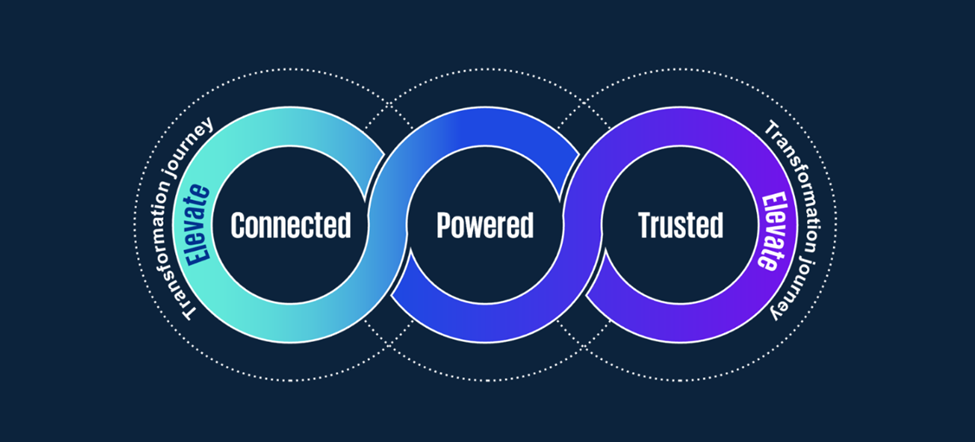

Lessons Learned from the Transformation Journey

One of the biggest lessons from digital transformation in supply chain management is the importance of leadership buy-in and effective change management. Moving from legacy vs modern supply chains requires more than just adopting new tools—it demands a cultural shift and strategic alignment across the organization. Leaders must champion the vision, allocate resources, and foster collaboration to ensure employees embrace the change. Equally critical is the integration of systems across the value chain. Cloud supply chain platforms and smart logistics solutions enable seamless information flow between suppliers, manufacturers, and distributors, breaking down silos and creating true supply chain visibility. Without integration, even the most advanced tools risk becoming isolated fixes rather than enablers of end-to-end transformation. Another key lesson is the value of building a data-driven decision-making culture. AI in logistics and supply chain automation provide real-time insights, but organizations must learn to trust and act on these analytics to fully capture their benefits. Companies that succeed often start small, focusing on scalable digital initiatives that deliver measurable results before expanding. This iterative approach reduces risk while building confidence in new systems. Ultimately, the journey highlights that digital transformation in supply chain operations is not a one-time project but an ongoing evolution toward agility, transparency, and resilience.

Conclusion

The journey from legacy vs modern supply chains shows just how transformative technology can be. Before, organizations relied on manual workflows, siloed data, and reactive problem-solving; after, they gained supply chain visibility, real-time tracking, and predictive insights powered by AI in logistics. With smart logistics solutions, cloud supply chain platforms, and supply chain automation, businesses have reduced costs, improved resilience, and elevated customer satisfaction. Digital transformation in supply chain management is not only about efficiency today but also about future-proofing operations against tomorrow’s disruptions. If your supply chain still relies on legacy processes, now is the time to start your transformation journey.